The first time I held a lap steel guitar kit in my hands, I felt a rush of excitement I hadn’t experienced in years. As a luthier with nearly three decades of experience, I thought I’d seen it all. But there I was, like a kid on Christmas morning, about to embark on a journey that would reignite my passion for instrument building. Little did I know, this simple kit would lead me to discover groundbreaking techniques that would revolutionize the way we approach lap steel guitar construction.

In this guide, I’ll share the fruits of my labor and the insights I’ve gained through my work with the Savart Journal. From selecting the perfect kit to fine-tuning your creation, we’ll explore every aspect of building your own slide guitar. Whether you’re a seasoned builder or a curious beginner, get ready to unlock the secrets of crafting a lap steel guitar that sings with your unique voice.

Understanding Lap Steel Guitar Kits

Components of a Lap Steel Guitar Kit

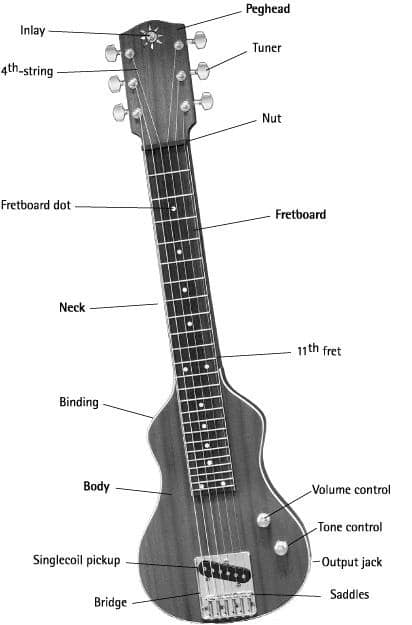

As an acoustics researcher, I’ve delved deep into the components that make a lap steel guitar sing. The body, typically made of wood or metal, forms the foundation of the instrument’s resonance. The neck and fretboard are crucial for playability and intonation. One often overlooked element is the bridge. Lap steel guitar bridges come in various designs, from simple fixed types to more complex adjustable versions. These bridges significantly impact the instrument’s sustain and tonal characteristics.

The pickup system is another vital component, translating string vibrations into electrical signals. Single-coil pickups offer crisp, bright tones, while humbuckers provide a warmer, fuller sound. The electronics, including volume and tone controls, allow for further sound shaping. Understanding these components and their interactions is key to building a lap steel guitar that not only looks great but delivers the rich, evocative tones that define this unique instrument.

Types of Lap Steel Guitar Kits

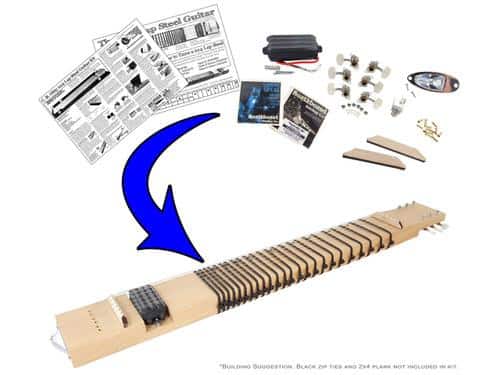

As an editor of stringed instrument books, I’ve encountered a fascinating array of lap steel guitar kits. These kits cater to various skill levels and preferences. For beginners, there are simplified kits with pre-drilled bodies and pre-wired electronics, making assembly a breeze. Intermediate builders might opt for semi-customizable kits, offering more flexibility in design and components. For the true enthusiasts, there are advanced kits that provide a blank canvas, allowing for complete customization from scratch. It’s worth noting that many of these kits share similarities with electric guitar kits, particularly in their electronic components. However, the unique body shape and playing style of lap steel guitars necessitate specialized designs. Understanding these distinctions is crucial when selecting the right kit for your project.

Benefits of Building Your Own Lap Steel Guitar

Customization Options

As a luthier with a focus on ergonomics, I’ve learned that customization is key to creating the perfect instrument. When you build your own lap steel guitar, you’re not just assembling parts; you’re crafting an extension of yourself. The ability to fine-tune every aspect of your instrument is invaluable. From choosing the wood for optimal resonance to adjusting the action for your playing style, each decision enhances your connection with the guitar.

One of my favorite customization options is the double neck lap steel. This configuration allows for quick transitions between tunings, expanding your sonic palette. You can also experiment with pickup combinations, bridge materials, and even body shapes. The beauty of building your own is that you’re not limited by mass-production constraints. Your lap steel can be as unique as your playing style, perfectly tailored to your needs and preferences.

Cost-Effectiveness

As someone who’s managed the Liutaio David Garcia Lutherie Information website, I can confidently say that building your own lap steel guitar is incredibly cost-effective. Through my research, I’ve found that DIY lap steel projects can save you up to 50% compared to purchasing a ready-made instrument. The raw materials and components are relatively inexpensive, and by eliminating labor costs, you’re investing primarily in your own time and skill development.

Moreover, the value proposition extends beyond mere savings. You’re not just getting a guitar; you’re gaining an intimate understanding of its construction and mechanics. This knowledge proves invaluable for future maintenance and modifications. In my experience, musicians who build their own instruments often find themselves more connected to their craft, leading to enhanced creativity and performance. The cost-effectiveness of a DIY lap steel isn’t just about money—it’s an investment in your musical journey.

Step-by-Step Guide to Building a Lap Steel Guitar

Preparing Your Workspace

Before diving into your lap steel guitar kit, I always stress the importance of preparing your workspace. A well-organized area is crucial for a smooth build process. From my years of crafting instruments, I’ve learned that a clean, spacious surface not only makes assembly easier but also protects your kit components. I recommend setting up a sturdy table with ample lighting and ventilation. Lay out your tools within easy reach – you’ll need screwdrivers, pliers, and a soldering iron for electronics. Don’t forget a soft cloth to protect the guitar’s finish as you work. Having everything at your fingertips minimizes interruptions and keeps you focused on the task at hand. With your workspace ready, you’ll be well-prepared to tackle the exciting journey of assembling your own lap steel guitar.

Assembling the Body and Neck

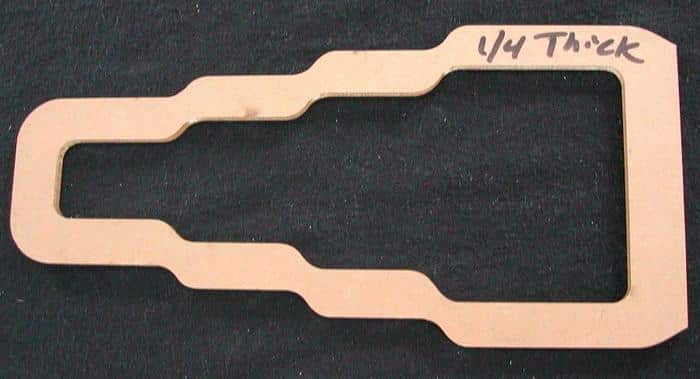

As I begin assembling the body and neck, I’m acutely aware of how crucial this step is for the instrument’s overall sound. My studies in acoustics have shown that the lap steel guitar parts must be perfectly aligned to achieve optimal tonal resonance. I carefully position the neck, ensuring it’s flush with the body. Years of experience have taught me that even a slight misalignment can dramatically affect the guitar’s sustain and vibration transfer.

I apply a thin layer of wood glue, being meticulous not to use too much, as excess can dampen vibrations. As I clamp the pieces together, I double-check the alignment, knowing that this join will be the heart of the instrument’s sound. The satisfaction of seeing these lap steel guitar parts come together is immense, knowing that each precise step contributes to the unique voice of this custom-built lap steel.

Installing Electronics and Hardware

Now that we’ve assembled the body and neck, it’s time for the exciting part: installing the electronics and hardware. As a former engineer, I approach this step with meticulous attention to detail. First, I carefully position the lap steel guitar bridges, ensuring precise alignment for optimal string vibration and sound transfer. Then, I meticulously solder the pickup connections, making sure each joint is clean and secure to prevent unwanted noise.

I always double-check the wiring diagram before connecting the volume and tone potentiometers. It’s crucial to achieve clean, noise-free connections for the best possible sound quality. Finally, I install the tuning machines, taking care to align them perfectly for smooth operation. This step is where your lap steel guitar truly comes to life, and the satisfaction of seeing it all come together is unparalleled.

Stringing and Tuning

Now it’s time for stringing and tuning, the final steps that breathe life into your lap steel guitar. I’ve spent years perfecting this process, and I’m excited to share my insights. First, select high-quality lap steel guitar strings that match your desired tone and playing style. I prefer nickel-wound strings for their warm, rich sound, but experiment to find your preference.

Carefully thread each string through the tailpiece and over the bridge, ensuring proper alignment. As you wind the strings onto the tuning pegs, maintain tension to prevent slippage. Proper string installation is crucial for stability and intonation. Once all strings are in place, begin tuning. I recommend starting with an open G tuning (D-G-D-G-B-D) for beginners, but don’t be afraid to explore alternative tunings as you progress. Remember, patience is key during this process. Fine-tune each string multiple times to account for initial stretching.

Tips for Choosing the Right Lap Steel Guitar Kit

Factors to Consider

When selecting a lap steel guitar kit, several crucial factors demand your attention. Through my experiences with the New England Luthiers group, I’ve learned that wood quality significantly impacts tone and sustainability. Look for kits featuring solid hardwoods like maple or mahogany. The pickup quality is equally vital; I recommend seeking out kits with reputable brand-name pickups for optimal sound. Don’t overlook the hardware components – tuners, bridge, and nut all play crucial roles in playability and intonation.

Consider your skill level and the tools you have access to. Some kits require more advanced woodworking skills, while others are more beginner-friendly. Lastly, factor in customization options. The best kits offer flexibility in finish choices and electronic configurations, allowing you to create a truly unique instrument. By carefully weighing these aspects, you’ll be well-equipped to choose a lap steel guitar kit that aligns with your vision and skill set.

Popular Brands and Models

In my experience reviewing lap steel guitar kits, I’ve found that certain brands consistently deliver quality and value. Eastwood and StewMac are two manufacturers that stand out for their comprehensive kits and excellent customer support. These brands often include components that rival those found in professional-grade instruments, making them ideal for serious enthusiasts.

For beginners, I recommend considering Saga’s LJ-2 kit, which offers a great balance of affordability and quality. More advanced builders might appreciate the Precision Pearl kit, which allows for greater customization. It’s worth noting that while these kits focus on lap steel guitars, many of the skills you’ll develop are transferable to building other instruments, including pedal steel guitars. As you explore different models, pay attention to the wood quality, electronics, and hardware included – these elements significantly impact the final sound and playability of your instrument.

FAQs

What is a lap steel guitar kit?

A lap steel guitar kit is a package that contains all the necessary components to build your own lap steel guitar. These kits typically include the body, neck, hardware, electronics, and instructions for assembly. They allow guitar enthusiasts to create a custom instrument while learning about its construction.

What tools do I need to build a lap steel guitar kit?

To build a lap steel guitar kit, you’ll typically need the following tools:

- Screwdrivers (flathead and Phillips)

- Pliers

- Wire cutters

- Soldering iron and solder

- Ruler or measuring tape

- Sandpaper

- Wood glue

- Allen wrenches (sizes may vary depending on the kit)

How long does it take to build a lap steel guitar from a kit?

The time it takes to build a lap steel guitar from a kit can vary depending on your experience level and the complexity of the kit. For beginners, it might take anywhere from 10 to 20 hours spread over several days. More experienced builders might complete the project in 5 to 10 hours. It’s important to work at a comfortable pace and allow time for finish drying if you’re applying paint or lacquer.

What are the advantages of building your own lap steel guitar?

Building your own lap steel guitar offers several advantages:

- Cost savings compared to buying a pre-made instrument

- Ability to customize the guitar to your preferences

- Gain a deeper understanding of the instrument’s construction and mechanics

- Sense of accomplishment and personal connection to the instrument

- Opportunity to learn new skills in woodworking and basic electronics

What types of wood are commonly used in lap steel guitar kits?

Common woods used in lap steel guitar kits include:

- Mahogany: Offers a warm, rich tone and is relatively easy to work with

- Maple: Provides a bright, clear tone and is known for its durability

- Ash: Delivers a balanced tone with good sustain

- Alder: Produces a full, balanced sound and is lightweight

- Poplar: An affordable option that’s easy to work with and takes finish well

The choice of wood can affect the overall tone and appearance of your lap steel guitar.

Conclusion

Building a lap steel guitar is more than just crafting an instrument – it’s about creating a piece of yourself. Are you ready to start this transformative journey? After nearly three decades in lutherie, I can confidently say that embarking on a DIY slide guitar project is an adventure that will not only challenge you but also deeply reward you.

As we’ve explored in this guide, lap steel guitar kits offer an accessible entry point into the world of lutherie. From understanding the components to mastering the assembly process, you’re now equipped with the knowledge to bring your own unique instrument to life. Remember, the beauty of building your own lap steel lies not just in the cost-effectiveness or customization options, but in the personal connection you’ll forge with your instrument.

So, pick up those tools, choose your kit wisely, and let your creativity flow. Your journey into the art of DIY slide guitar making begins now. Happy building!

Hey, Mr. David Garcia. Thanks for this information. I appreciate your insights and I’m going to StewMac right now to find a kit.