Imagine, if you will, holding in your hand a guitar pick unlike any other – a pick that represents a revolution in guitar-playing technology. A small, seemingly innocuous object, but one that signifies a new frontier in the melding of music and technology. This is my first encounter with a 3D-printed guitar pick.

With each strum, I felt a profound shift in my approach to guitar playing. This wasn’t just a slight change in thickness or material; this was a complete transformation. The pick’s perfectly tailored design, its bespoke comfort, even its unique aesthetic – all of these were clear indications of a new era of customisability ushered in by 3D printing technology. But it was the sound, that distinctive resonance, that truly blew me away. The conclusion of this transformative journey? Well, you’ll have to stick around to find out.

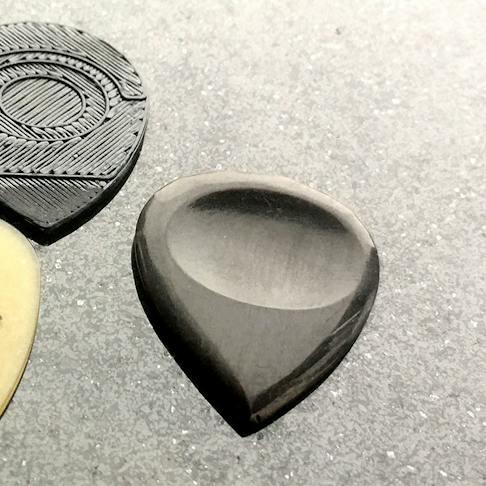

Stepping into my workshop, long-buried beneath an avalanche of wood shavings and guitar parts, I beheld this pick with something akin to reverence. For a seasoned luthier like myself, who loves delving into the minute details of guitar anatomy, the discovery of 3D printed picks felt like an unexpected leap into the future.

The uncharted territory of 3D-printed guitar picks is a world rife with innovation, excitement and a touch of the unknown. Armchair luthiers and experienced craftspeople alike are on the brink of something truly revolutionary, where the only limit is the reaches of their imagination. This is the story of my personal exploration into this thrilling realm and, more importantly, it’s your comprehensive guide to navigating and mastering it yourself.

So, whether you’re a guitar enthusiast looking to dabble in new tech, or a luthier like me, captivated by the opportunity to reshape our approach to a guitar’s sound, this is our journey to take together. Shall we step into the future?

Feasibility of 3D-Printed Guitar Picks

Quality and Comparisons

Delving deeper into the feasibility of 3D-printed guitar picks, quality and comparisons is a significant factor to consider. As a dedicated guitarist and technophile, I was initially cautious. Testing 3D-printed guitar picks with a strong emphasis on their quality and performance felt like uncharted territory. Could a plastic pick churned out by a printer truly measure up to a traditionally produced one?

After countless rounds of playtests and examinations with my own acoustic guitar and a variety of these picks, I must say, my initial skepticism was challenged. Notably, the quality of sound produced by a 3D-printed PLA (Polylactic Acid) pick was quite impressive. The tone created by the PLA pick, when strumming on an acoustic guitar, was rich and solid, certainly standing up to more traditional picks.

I began analyzing the feel of the pick. I was pleasantly surprised by the weight, rigidity, and the durability that 3D-printing offered. Many have the notion that a 3D-printed object may be brittle or flimsy, however, the 3D-printed guitar pick quality was impressive, and any concerns regarding strength or life-span were promptly laid to rest. They were as comfortable and robust to use as any conventional pick in my collection.

Moreover, each acoustic guitar PLA pick had (thanks to the wonders of 3D printing) a level of personalization that traditional manufacturing simply cannot provide. The ability to tweak, adjust, and completely customize your pick can revolutionize the way you approach your instrument, paving the way for unique tonal landscapes and playing styles.

In conclusion, a 3D-printed guitar pick is not just a novel idea; it’s a practical alternative. Parallel in quality, and superior in customization, they have the potential to cater to the needs of professional and hobbyist guitarists alike. Rest assured, we will still delve deeper into the world of 3D-printed guitar picks, examining the different materials and manufacturing processes available, as well as diving into existing models and designs you might use for inspiration.

Materials and Manufacturing

Having ventured into the art of blending tech and music, my background as an engineer afforded me an insightful understanding of the role that materials and manufacturing processes play in creating 3D-printed guitar picks. Let’s unpack the subtle orchestration of technological prowess and acoustic brilliance, notably the influence of materials like PLA in crafting guitar picks and the additive manufacturing methods employed.

Primarily, a significant material used in 3D printing guitar picks is Polylactic Acid or PLA. Structurally robust and eco-friendly, PLA guitar picks have proved instrumental in delivering an unparalleled balance of control and flexibility. Its rigidity ensures a noteworthy response, while its slight flexibility mitigates the risk of breakage or damage. More importantly, PLA’s environmental footprint, being a bioplastic derived from renewable resources, augments its appeal.

The use of PLA turns a new leaf in the realm of guitaring, radically altering how we perceive the conventional pick. Imagine strumming your guitar with an eco-friendly pick that not only exudes performance but is a testament to sustainable practices in music. Truly a symphony to revel in!

A profound understanding of additive manufacturing for guitar accessories is the unsung hero behind the creation of high-quality 3D-printed picks. Unlike traditional methods that subtract or carve out materials, additive manufacturing builds the object layer by layer from the ground up, thereby reducing waste and enabling intricate designs. The symphony that oozed from my guitar, with every strum of the PLA pick, resonated the meticulous layers crafted through additive manufacturing.

The choice of 3D-printing materials for picks plays a remarkable role in conferring specific attributes to the instrument. Apart from PLA, materials like ABS and Nylon can also be used, each contributing distinctive characteristics to the pick. ABS, known for its toughness, can cater to robust playing styles, while Nylon, famed for its flexibility, can lend a softer touch. Remember, the choice of materials isn’t merely about sustainability and performance; it has a significant impact on the acoustic nuances that your pick can pull off.

Moving forward, exploring the varied materials and mastering the science behind additive manufacturing can lead to improved designs, customizations, and ultimately, better music. As we tune into the next section, get ready to dive into the world of models and designs for 3D-printed guitar picks. Every layer, every material, and every design choice is our symphony to co-create.

Models and Designs for 3D-Printed Picks

Finding Designs

Transitioning from our explorations of materials and manufacturing, let’s delve into the exciting realm of finding viable designs for 3D-printed guitar picks. The journey through the maze of digital designs felt like traversing an endless art gallery, astounding me with the variety it offered. My experience with 3D guitar pick designs spans basic models to intricate designs that appeared as exquisite pieces of art.

When it comes to downloadable guitar pick STL files, the internet is a veritable goldmine. Bubbling over with communities of creatives, you’ll come across an astonishing array of models ready to be 3D printed. Everything from practical no-frills designs to intricate and elaborate models, each with their unique character, is up for grabs.

From my experience, harnessing the potential of these designs also entails a clear understanding of your precise needs and personal preferences. Are you all about the music, searching for something simple, functional, and robust? Or are you a lover of aesthetics, drawn to intricate designs? Knowing the kind of guitar pick you’re aiming to produce would significantly streamline your search.

Another pivotal factor is the quality of the design files themselves. One should ensure that the designs are professionally rendered and compatible with your chosen software and 3D printer. This can be checked quite readily by viewing the user reviews and ratings on the download pages. Always remember, though, the essence of 3D printing lies in combining artistic aesthetics with mechanical soundness.

To conclude this journey through the gallery of 3D guitar pick designs, I must say it’s a diverse and dynamic universe out there. And while choosing a design might seem akin to finding a needle in a haystack, trust me when I say—the quest is half the fun. The delight of stumbling upon the perfect design to suit your unique style is well worth the pursuit.

Now that we’ve armed ourselves with the desired designs, it’s time to cast our glance on the 3D models themselves. Let’s jump right into the intricacies of understanding 3D models in the next section, ensuring our 3D-printed guitar picks result in sonorous success.

Understanding 3D Models

Let’s delve deeper into the intriguing world of guitar pick 3D models, an integral part of the fabrication process. As someone who has dedicated his life to understanding the intricacies of stringed instruments, unraveling the complexities of 3D models was a beneficiary challenge. Allow me to simplify the seemingly esoteric realm for you.

At their core, 3D models are a precise and intricate digital docket of a guitar pick. They’re essentially a virtual blueprint in which every millimeter is scrupulously measured and crafted, including the tip’s thickness, grip intensity, and overall dimensions. It’s vital to comprehend that 3D models aren’t mere visual renditions but interactive mockups built with special software and can be manipulated, revised, and replicated multiple times.

Grasping the nuances of guitar pick 3D models is pivotal in understanding the outcome of what will be physically produced. The true utility and brilliance of 3D modeling shine when the material science is considered. This involves understanding how the virtual representation will mold reality, considering the properties of the material the 3D-printed picks will be made of – how rigid, flexible, or tough it will be, and how these characteristics will impact the final design.

Take, for instance, 3D models contribute remarkably to evaluating how the pick will land on the string, the character of its sounds, and even its durability. Every aspect of your interaction with the guitar, from the grip to the strum, is considered and designed with precision making the design topology a paramount factor in the final performance.

Understanding 3D models’ relevance to creating your custom guitar pick imparts a truly hands-on experience. Delving deep into it teaches us about the interplay of design, material, and, most importantly, acoustics. Furthermore, being more discerning with the impact of design topology lets you experiment and innovate, leading to the creation of a pick with immense precision and personal touch.

A deft understanding of 3D models is imperative to harness the possibilities of superbly 3D-printed guitar picks. Next, we’ll guide you through finding and adapting existing designs to make them your own, leveraging 3D modeling to its fullest potential.

Printing Your Own Guitar Pick

3D Printing Process

Okay, let’s dive into the meat of it – how to actually carve your own DIY 3D-printed guitar pick using the 3D printing process. For me, this is where the magic happens. When all my thoughts, designs and understanding of materials come together to create a physical piece of equipment that impacts my music.

First things first, you need a 3D printer. There are a range of affordable options available, and while it may seem like a large investment initially, it’s one that’s certainly paid dividends in my journey. Once you have your printer, it’s all about the 3D printer settings for guitar picks. I spent long hours, through many a late-night session, experimenting with different configurations to find the right balance between durability and flexibility. My key takeaway? A slow print speed and high fill density were critical in getting the kind of sturdy, resilient pick I was after.

Next up, choosing the material. I leaned towards PLA plastic due to its sturdy nature and versatility. I loved playing around with all the color variations! I also spent time exploring other materials like ABS and Nylon, even trying a few wood-infused filaments. However, the sound quality, overall finish, and strength of the PLA picks remained unmatched. So, in the end, PLA won my vote.

The process begins with preheating the printer. Upon reaching my optimal temperature of 185°C for PLA filament, I initiate the print job. It is a moment of anticipation, staring at the printer as it methodically starts to layer the material, slowly but surely, bringing my design to life. The entire process generally takes between 20 to 30 minutes – a short wait for a creation that feels deeply personal.

Once the pick is ready, some post-printing work is often needed. Removing excess material, smoothing edges with a bit of sandpaper, examining your pick for any structural flaws, and then the ultimate testament – playing it on your instrument. Sometimes it takes a few iterations to get it right, but trust me, the satisfaction of strumming with your DIY 3D-printed guitar pick makes it all worthwhile.

In the next section, I’ll give you a practical guide to help prepare you for this process and answer the frequently asked questions.

Practical Guide to Printing

Building on my depth of experience in lutherie and the valuable insights gained from utilizing 3D printing technology for effective customization, I’ve designed an easy-to-follow, expert guide for printing your own guitar picks. As we delve more into the practical aspects of a ‘Guitar Pick Printing Guide’, it is essential to remember the accuracy, adaptability, and freedom that this technology brings to pick creation.

Preparing to Print: Start by ensuring the correct setup of your 3D printer. Check if all the moving parts are working smoothly, the software is correctly implemented, and the build plate is well-leveled.

Understanding Filament Application: In the context of guitar picks, a filament with a bit of flexibility, such as TPU or Nylon, is preferable. These materials promise durability while providing a feel similar to traditional picks. For printing, regulate your filament’s temperature and flow rate based on the manufacturer’s recommendations and personal experimentation.

Slicer Settings: Depending on the guitar pick model you’ve chosen, you will need to adjust certain slicing settings. Keep an eye on layer height, print speed, and cooling settings. A lower layer height can provide impeccable detail and smoothness, suiting the precision often desired in a guitar pick.

It is wise to plan your print’s orientation optimally. With guitar picks, laying them flat on the build surface usually yields the best results. It ensures consistent thickness across the pick and eliminates stepping on the grip area.

Controlled Post-Print Process: After the printing completes, allow the printed picks to cool down before removing them from the build plate. Subsequently, any supports or blemishes from 3D printing can be carefully trimmed away.

Now you’ve produced your first batch of custom 3D-printed guitar picks. Don’t be discouraged if the results aren’t perfect right away – I’ve found that persistent fine-tuning and practice lead to encouraging improvements. This process truly makes us appreciate the beautiful fusion of technology and craftsmanship in creating personalized, 3D-printed guitar picks.

In the following section, we’ll further explore the intricate steps of the 3D printing process to enhance your understanding and proficiency in printing your own picks. With a deeper comprehension and practice, the opportunities to customize your music-making tools are boundless.

FAQs

What are 3D-printed guitar picks?

How are 3D-printed guitar picks made?

Why should I use 3D-printed guitar picks?

Where can I get 3D-printed guitar picks?

Conclusion

‘3D-printed picks: a passing fad or a game-changer? Let’s summarize the journey and see where the future lies.’ In this voyage through the world of 3D-printed guitar picks, the exploration has been as exciting as the revelation of their potential. We marveled at the possibilities presented by modern technology – the ability to shape your pick thickness to your playing style, to create custom designs, and to replicate coveted models. For the first time, the guitar pick, so often overlooked, took center stage.

I discovered the layered complexity involved in material selection, offering varied tones and durability attributes. The knowledge that the industrial-grade plastic used in manufacturing traditional picks can be emulated and even improved upon with 3D printing was a major milestone. Who knew there was so much hidden depth behind a seemingly simple pick?

Unearthing a trove of printable designs online, the guidance to understanding these 3D models further demystified the process. The promise of sustainability further tipped the scales in favor of 3D-printed picks. My first-hand experience with printing and testing these picks further emphasized their tangible potential.

If I could provide one significant takeaway from our exploration, it would be: the future of guitar picks is not just in the hands of mass manufacturers anymore. If you are armed with a 3D printer and the right knowledge, it’s all right at your fingertips. Will 3D-printed guitar picks replace traditional ones wholesale? Perhaps, perhaps not. Yet, they certainly do provide an alternative, offering customization and accessibility hitherto unimagined. So, are 3D-printed guitar picks a passing fad? In my view, they are here to stay. The potential they hold for creativity, personalization, and sustainability issues a compelling argument for their continued evolution and use.